Guonuo's L-type sealer machine has our specific characteristics as below.

- Fully automatic

- L-sealing

- Big Man-machine interface

- Adopts import PLC

- Preset programs

- Digital display

- Pre-settable product counters

- Alarm display

- Waste film recycling

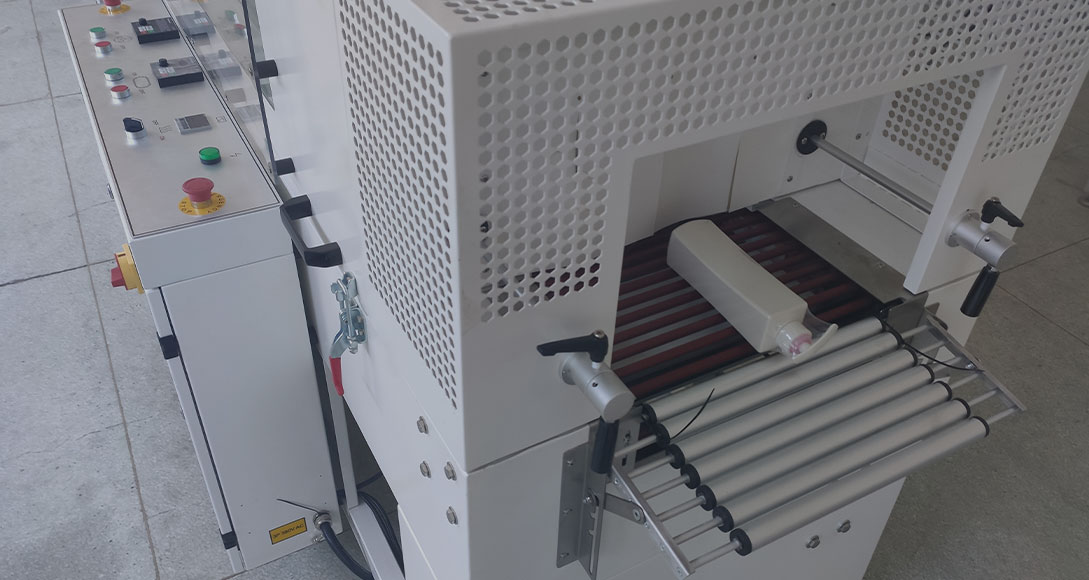

- Stable conveyor

- Easy to replace film

The L-sealer for sale only uses center-folded film which can be made by bopp, pe, or other heat shrink film.

As the film is pulled off the roll, a flat and horizontal guide/loading tray separates the two layers. One layer is under the tray and the other is held above the tray. This allows the operator to place the product on the tray between the two layers of film in the corner formed by the fold and the front edge of the film.

The film, containing the product, is pulled forward into the sealing area. A sealing bar in the form of an “L” is pulled down. After the conveyor feeds the product into the film, the L-bar sealer machine can measure the length of the product and perform sealing automatically by the sensor and the sealing jaws.

Once sealed, the closed pouch is then moved into a heat shrink tunnel by the soft conveyor automatically, shrinking and tightening the film. The left lateral film which is trimmed off during the packaging process is automatically rolled up on a waste film recycle reel after the sealing and cutting.